See whats ahead.

Transform your manufacturing operations with predictive AI that tells you exactly what's happening, why, and what to do about it.

While competitors only flash a check engine light and suggest you investigate multiple failure modes, we identify the specific defective parts and failure modes, providing detailed repair recommendations. This enables effective planning and scheduling to maximize throughput and minimize costs.

The Manufacturing Reality Check

Most factories operate like 1950s race cars - reactive, inefficient, and constantly playing catch-up. Basic vibration and temperature monitoring only tells you something might be wrong, burdening your planning efforts. Don't waste time and parts guessing the problem. Our experts identify exact parts and failure modes, providing clear solutions with minimal doubt. Stop losing money on unexpected downtime, over-maintenance, unnecessary MRO spend, and missed optimization opportunities.

Unexpected equipment failures costing thousands per hour

Your Formula One Advantage

Take advantage of our domain knowledge, analysts and AI models. Data without analytics is of no value. Let us convert your dozens of data sources into actionable intelligence.

Precise Analytics

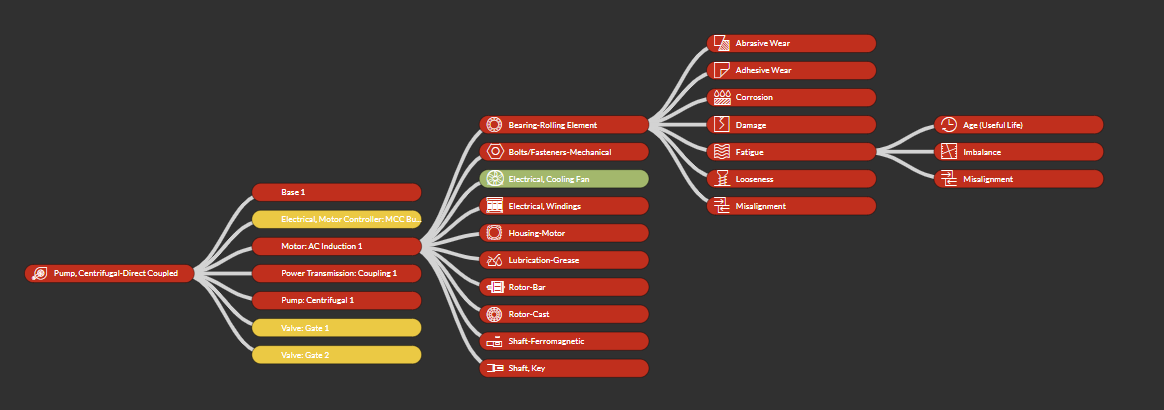

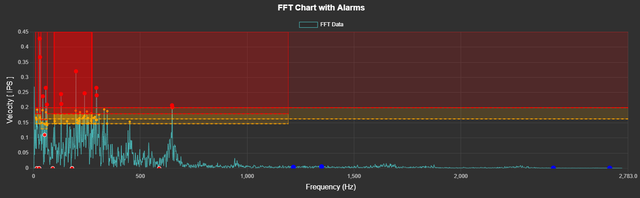

All analysis and actionable prescriptions target specific parts and failure modes. We identify exact components and defects—never just suggest you "go inspect for possible problems."

Beyond Basic Monitoring

We capture complete waveform and FFT data for comprehensive vibration analysis to identify all failure modes.

High-resolution electrical signature analysis monitors motor failures across AC, DC, and servo applications, plus transformer health, harmonic distortion, power quality, and driven components.

Additional capabilities include ultrasonic analysis (air-borne, mechanical, electrical), lubrication analysis, thermal imaging for mechanical/electrical assets, and process data monitoring (pressure, flow, temperature, level, voltage, current, line speed, weather, utilities).

Actionable Prescriptions

Get specific maintenance actions, not generic alerts

How We Transform Your Operations

Predictive Intelligence

Advanced AI and machine learning that goes far beyond basic condition monitoring to deliver precise failure predictions.

Data-to-Dollars Optimization

We start with value and work backwards to identify exactly what data you need - no more data exhaust.

Multi-Technology Integration

Seamlessly integrate asset performance data with process data for complete operational visibility.

Workforce Empowerment

Connect your team to actionable insights that make them faster and more powerful every day.

Why Factory Leaders Choose Nth Corner

Data to Dollars

All data that hasn't been validated and mapped to actual VALUE is just data exhaust. We help you turn information into profit.

The People

Our team brings unmatched real-world experience. As Farmers Insurance says, "we know a lot because we have seen a lot" - in our case, "we know a lot because we have DONE a lot!"

Multi-Technology PLUS Process Data

While the industry has been promising integrated asset and process data for three decades, we actually deliver it. Every asset component and process operation has hundreds of failure modes, without the right validated data, you're flying blind.

Proven Results

- Monitor, detect, and prevent manufacturing downtime

- Lower costs, higher output, better quality

- Meaningful profits that pay for themselves in under two years