The Difference Between Knowing and Doing

Most consultancies talk about predictive maintenance. We've spent decades actually delivering it. While our competitors offer theories and generic solutions, we bring battle-tested experience from thousands of implementations across every major manufacturing sector.

The difference? We don't just know a lot because we've seen a lot—we know a lot because we've DONE a lot.

The People: Unmatched Real-World Experience

Our team of Founders, Key Team Members, and Technical Advisors brings a level of expertise that simply doesn't exist elsewhere in the Asset Performance Management market. This isn't a team of software developers trying to understand manufacturing—these are industry veterans who have:

- Benchmarked over 1,400 locations across every vertical market

- Implemented reliability programs at Fortune 100 manufacturers

- Delivered over $20 million in documented value to clients in manufacturing and processing sectors

- Achieved $50 million productivity increases within two-year timeframes

- Served in crisis response situations from BP's Deepwater Horizon to military logistics operations

- Pioneered condition monitoring programs since the 1990s

When you work with Nth Corner, you're not getting junior analysts learning on your equipment. You're getting certified reliability engineers, former military specialists, published industry authors, and executives who have led transformations at the world's most demanding manufacturing operations.

Data to Dollars: Eliminating Data Exhaust

Here's the truth that no one else in the industry wants to admit: All data that hasn't been validated and mapped to actual VALUE is just DATA EXHAUST.

For three decades, the Asset Performance Management market has been collecting more and more data—vibration sensors, temperature monitors, IoT devices everywhere. But more data doesn't equal more value. In fact, it often creates more confusion.

How We're Different

We start with value and work backwards to identify exactly what data you need.

Instead of drowning you in dashboards and metrics that don't drive decisions, we:

- Identify your specific value drivers - What actually impacts your bottom line?

- Map data to those outcomes - Which signals predict problems that affect those drivers?

- Eliminate the noise - Remove data collection that doesn't contribute to value

- Validate continuously - Ensure the data-to-dollars connection remains strong

This isn't theoretical. Our approach is built on proven methodologies documented in industry whitepapers and refined through decades of implementation.

The Result: Every data point you collect serves a purpose. Every alert you receive is actionable. Every dollar you invest returns measurable value—typically paying for itself in under two years.

Multi-Technology PLUS Process Data: The Integration That Actually Works

The industry has been promising integrated asset and process data since the 1990s. We're the ones who actually deliver it.

The Problem Everyone Else Ignores

Most organizations have reverted to being over-subscribed to just one or two monitoring technologies. They track vibration and temperature, maybe add some ultrasonic monitoring—but they're missing the complete picture.

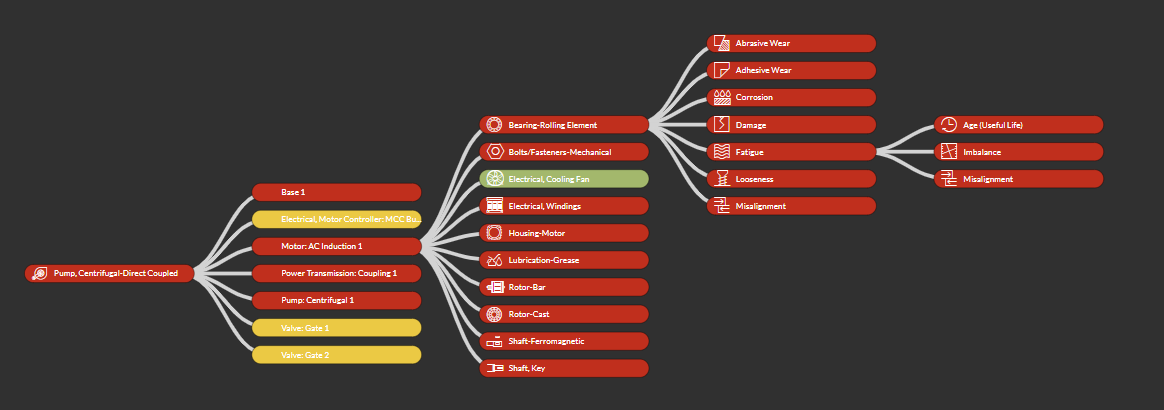

Here's what they don't tell you: Each component of an asset and each unit operation of a process has dozens, hundreds, or even thousands of potential failure modes.

Without the right validated data, you have no idea:

- What impact your asset performance is having on your process

- What impact your process performance is having on your assets

- Which failure mode is actually developing

- When that failure will occur

- What specific action will prevent it

Our Comprehensive Approach

We integrate ALL the technologies needed to understand both Asset Health AND Process Health:

Condition Monitoring Technologies:

- High-resolution vibration analysis (complete waveform and FFT data)

- Electrical signature analysis (AC, DC, servo motors, transformers, power quality)

- Ultrasonic analysis (air-borne, mechanical, electrical)

- Lubrication analysis

- Thermal imaging (mechanical and electrical assets)

Process Data Integration:

- Pressure monitoring

- Flow measurement

- Temperature tracking

- Level sensing

- Voltage and current analysis

- Line speed monitoring

- Weather conditions

- Utilities performance

This isn't just collecting more data—it's intelligently integrating asset performance with process operations to understand the complete picture of your manufacturing system.

The Inputs: Complete Visibility Into Asset and Process Health

While competitors give you scattered data from individual sensors, we provide unified intelligence from all condition monitoring and process data sources.

What This Means for You:

- No blind spots in your asset monitoring

- Process impacts on equipment immediately visible

- Equipment impacts on process quality instantly identified

- Complete failure mode coverage across all critical assets

Our approach captures the full spectrum of data needed to predict failures before they occur and optimize performance continuously.

The Outputs: Specific Actions, Not Generic Alerts

What other give you VS what Nth Corner delivers:

The Engine: Nth Corner Software Platform

Built by Practitioners, For Practitioners

Nth Corner wasn't created as commercial software—it was born from necessity. When our reliability engineers and analysts were delivering condition monitoring reports globally, they discovered something critical: many customers were performing FMEA and RCA on the exact same assets and failure modes.

The solution was to standardize the capture of information, codify it, and make it available across the organization. This provided unprecedented consistency, accuracy, and speed to resolve issues and eliminate defects.

When customers saw the breadth and depth of information captured in Nth Corner, they asked how they could incorporate this knowledge into their own systems and leverage it to train their teams. That's when Nth Corner became a commercial platform.

What Makes Nth Corner Different

Curated Content by Experts

Nth Corner is built and continuously refined by maintenance and reliability professionals—not software developers. Every failure mode, every diagnostic criterion, every recommended action has been validated through real-world experience.

Confidence-Based Decision Making

Know your confidence factor for mitigating each specific defect. No more guessing whether an alert is reliable—Nth Corner tells you how certain the diagnosis is.

Embedded Knowledge

Failure-driven strategies and decades of data are embedded directly into the platform, enhancing your team's knowledge and capabilities with every use.

Standardized Language

Common terminology and data structures empower frontline workers to communicate clearly and act decisively.

Intelligent Task Management

Nth Corner automatically removes tasks that are not quantitative or qualitative from your maintenance plans—eliminating busywork and focusing your team on what actually matters.

Comprehensive Analysis Capabilities

All analysis and actionable prescriptions target specific parts and failure modes:

- Vibration Analysis: Complete waveform and FFT data for comprehensive analysis identifying all failure modes

- Electrical Signature Analysis: High-resolution monitoring of motor failures across AC, DC, and servo applications, plus transformer health, harmonic distortion, and power quality

- Ultrasonic Analysis: Air-borne, mechanical, and electrical ultrasound monitoring

- Lubrication Analysis: Oil condition and contamination tracking

- Thermal Imaging: Mechanical and electrical asset temperature monitoring

- Process Data Integration: Pressure, flow, temperature, level, voltage, current, line speed, weather, and utilities

Every technology feeds into one unified intelligence platform that delivers specific maintenance actions, not generic alerts.